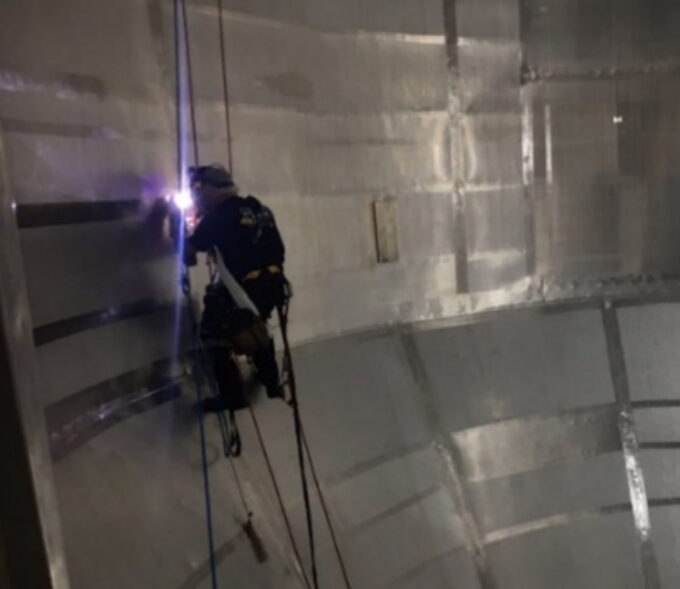

Thanks to our unique V-series crawler inspection robot – and in collaboration with rope access welding crews – Invert Robotics has replaced a 9-day inspection and repair cycle using scaffolding with a 1-day cycle with only minimal confined space access. Not surprisingly, by Europe’s largest and most advanced dairy processing plant has entrusted the inspection and repair of their vital assets to us for the third year running.

Our robotic crawler – with its 30x optical zoom camera – helps inspectors remotely find and localise even the smallest defects. Such defects are marked and logged for the repair crew, who follow close behind.

Benefiting from this technology, this major dairy processor achieves record turnaround times while increasing the accuracy and repeatability of asset inspection and repair.

Cutting costs, boosting safety

With 8 days’ less downtime and no need for scaffolding, the cost benefits are huge. But even more important are the safety aspects. The only people required in the asset are the welders. No scaffold builders or inspectors. And with the defects marked, the welders need spend only the minimum time necessary in any vessel.

Finally, no scaffolding means no risk of additional damage to the vulnerable stainless-steel surface of the dryers. No wonder that this state-of-the-art dairy plant is one of the growing number of companies who choose Invert Robotics to look after their critical production assets. For more information, please contact your local representative.