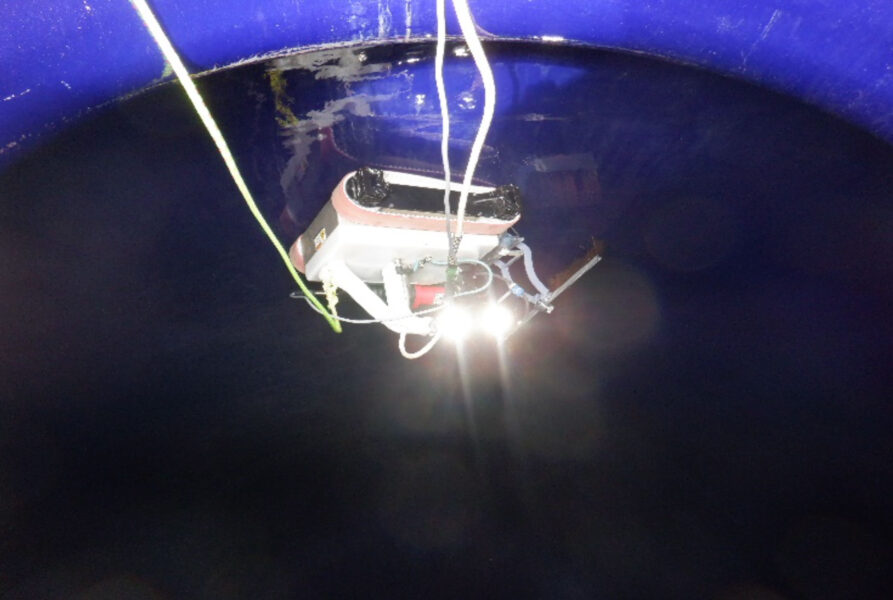

Partnering with SGS to help eliminate the need for confined space entry

Recently, we partnered with leading global inspection company SGS in Pakistan to carry out a Level 3 inspection and UT testing of horizonal, underground fuels tanks. Not only was the inspection safe – with no human entry into a confined space required – we got it done in under 4 days. Safety first The end […]

Efficient and effective asset inspections through knowledge sharing

Reducing costs while increasing efficiency, effectiveness and safety of asset inspections are top priorities for asset owners and maintenance managers. It’s why we at Invert Robotics partner with leading inspection companies to offer the best and most fitting inspection technologies for all asset inspections. Robotic solutions offer superiority to drone technology during inspection of wind […]

Visual inspection of carbon-steel boiler

Collaboration project between CS Energy – a major Australian electricity generator – and Invert Robotics results in the first remote inspection of a water tube boiler. As proponents of best practice and safety, CS Energy has a strict inspection schedule for its coal-fired boilers. Ranging from 40 to 60 meters in height, preliminary inspections are […]

Robotic crawler: accurate UT measurements in challenging situations

Using our unique robot platforms to take UT measurements on a range of different assets – both internal and external – without having to enter confined spaces or work at height. Ultrasound wall thickness measurements are important data to help determine the condition of assets. Reason why, Invert Robotics has integrated Olympus state-of- the-art UT […]

Visual inspection and spark testing of glass lined storage tank

Full inspection solution: combined visual and D/C spark-testing inspection of a 40-year-old glass lined storage tank used for the storage of benzyl chloride. Our unique hybrid-crawler was originally designed for inspections of glass lined vessels: the combination of magnets and vacuum for adhesion ensures that the robot can drive around safely in such assets, without […]

Robotic internal UT B-scans in a resin tank with heating coil

A complex inspection job: an insulated 600 m3 resin tank was equipped with a large heating coil on the floor, making scaffolding impractical. But a thin residue of resin on the walls meant our robotic crawler was challenged in ensuring sufficient adhesive power. With its unique combination of sliding cup suction technology and supporting magnets, […]

Inspección END combinada

Mediciones ultrasónicas e inspección visual de un depósito de acero al carbono. Los elevados niveles de corrosión y un interior atestado fueron los retos para la inspección de este recipiente. Mediante una rampa construida a medida y un robot versátil, Invert Robotics aportó toda la información solicitada relativa a todas las zonas del depósito de […]