Robotic internal UT B-scans in a resin tank with heating coil

A complex inspection job: an insulated 600 m3 resin tank was equipped with a large heating coil on the floor, making scaffolding impractical. But a thin residue of resin on the walls meant our robotic crawler was challenged in ensuring sufficient adhesive power. With its unique combination of sliding cup suction technology and supporting magnets, […]

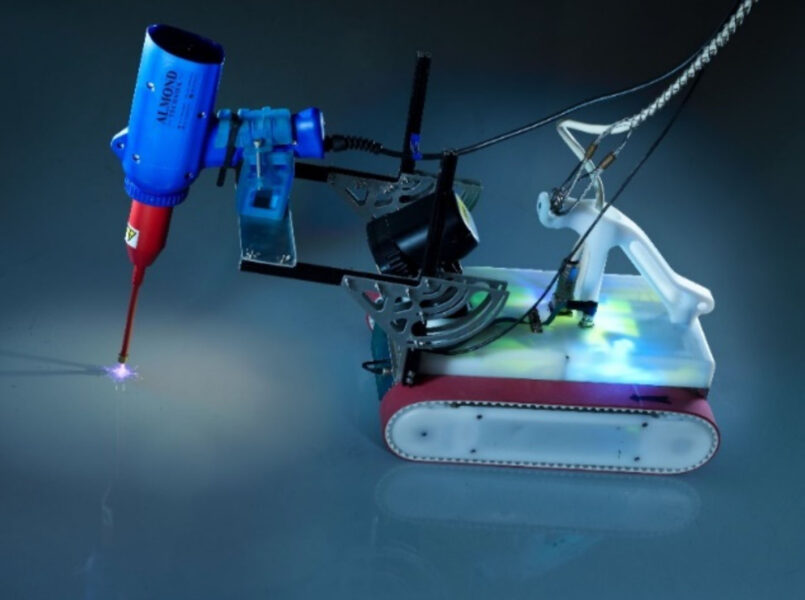

Spark testing ECTFE lining in a fibreglass reinforced polyester storage tank

Mounting a hand-held A/C spark tester on our unique vacuum robot, inspection of ECTFE lining welds was done remotely for the very first time at this major producer of zeolite products. Invert Robotics is continuously looking to add NDT-tools to our robot’s repertoire. A regular customer in the chemical industry required an inspection using spark […]

Collaborative project with major Dutch oil company results in first automated UT measurements in aluminium tank

Invert Robotics’ unique suction-based crawler inspection platform was used to take ultrasonic wall thickness measurements without the need for confined space entry. A major Dutch oil company approached Invert Robotics after a demonstration organised by Sprint Robotics. They asked us to add an Olympus DL38 ultrasonic thickness probe on our suction-based crawler platform. The objective […]

Using UT to inspect coal bin wear at a coal processing facility in Australia

In a collaborative project with a major Australian inspection services provider, Invert Robotics developed a custom M-serie robotic platform to take ultra-sonic wall thickness measurements without entering the confined space of a coal distribution hopper. Coal processing facilities utilise coal bins to manage the distribution of coal around there processing plants. The coal flows into […]

Successful remote 3D scan of iron ore chute at Western Australia mine

Invert Robotics developed a bespoke crawler inspection platform to obtain 3D scan data without entering the high risk confined space area below a 250,000 tonne iron ore stockpile. After a previous collaborative inspection with Invert Robotics, this mine in Western Australia once more called on us. This time they challenged us to devise a method […]

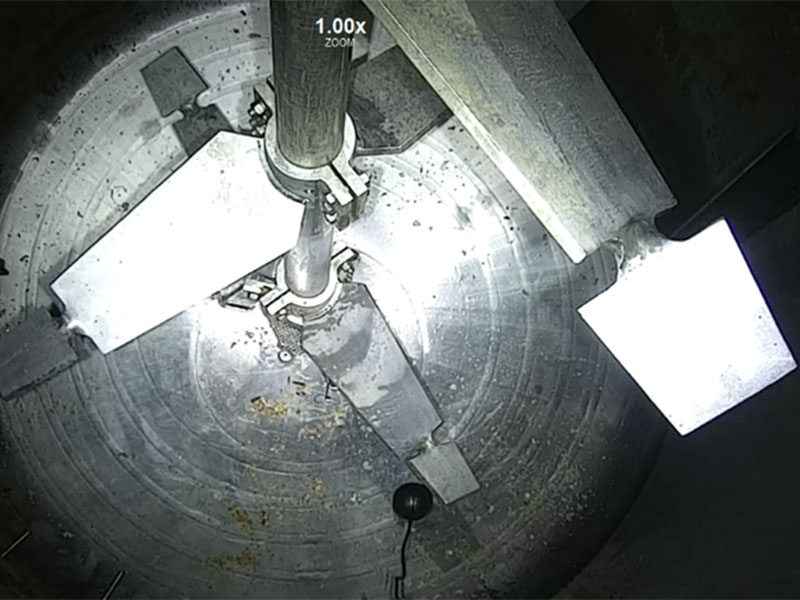

Certificeren van de Drukreactievaten

Laat de interne inspectie aan de robots over! De verplichte periodieke hercertificering van de reactieleiding onder druk vereist een interne visuele inspectie van de vaten. Invert Robotics leverde de camera en de robot zodat het inspectiebedrijf het betreden van afgesloten ruimtes kon vermijden. In West-Duitsland, dicht bij de grens met Nederland, staat een chemische fabriek […]

Gecombineerde NDT-inspectie

Ultrasone metingen en visuele inspectie van een koolstofstaal tank. Hoge corrosie-niveaus en een overvol interieur vormden de uitdagingen voor de inspectie van dit vat. Een op maat gemaakte hellingbaan en een veelzijdige robot zorgden ervoor dat Invert Robotics alle gevraagde informatie uit alle delen van de slibtank kon leveren Bij deze zeoliet productiefabriek, gelegen op […]