RCS Visual inspection of a 30-meter chimney in June 2023

En une seule journée, Invert Robotics a réalisé l’inspection visuelle d’une cheminée à l’aide d’un système de caméra RCS haute résolution. La cheminée en acier S235 mesure 30 mètres de haut et un mètre de diamètre. Réalisée par une équipe de deux techniciens formés et certifiés d’Invert Robotics et du spécialiste suisse de la […]

Inspections efficaces et efficientes des ressources grâce au partage des connaissances

La réduction des coûts ainsi que l’augmentation en parallèle de l’efficience, de l’efficacité et de la sécurité des inspections des ressources sont des priorités absolues pour les propriétaires des ressources et les responsables de la maintenance. C’est pourquoi, chez Invert Robotics, nous nous associons aux principales sociétés d’inspection afin d’offrir les meilleures technologies d’inspection, et […]

Inspections visuelles certifiées d’actifs de l’industrie chimique fortement réglementée

En tant qu’entreprise d’inspection robotique, nous sommes le partenaire d’inspection de confiance des principaux producteurs laitiers français. Grâce à notre savoir-faire éprouvé dans le secteur, nous avons été invités à effectuer une inspection d’essai des actifs sous pression dans une grande entreprise française de peinture et de revêtement. Découvrez ici comment nous avons également pu […]

Visual inspection of carbon-steel boiler

Collaboration project between CS Energy – a major Australian electricity generator – and Invert Robotics results in the first remote inspection of a water tube boiler. As proponents of best practice and safety, CS Energy has a strict inspection schedule for its coal-fired boilers. Ranging from 40 to 60 meters in height, preliminary inspections are […]

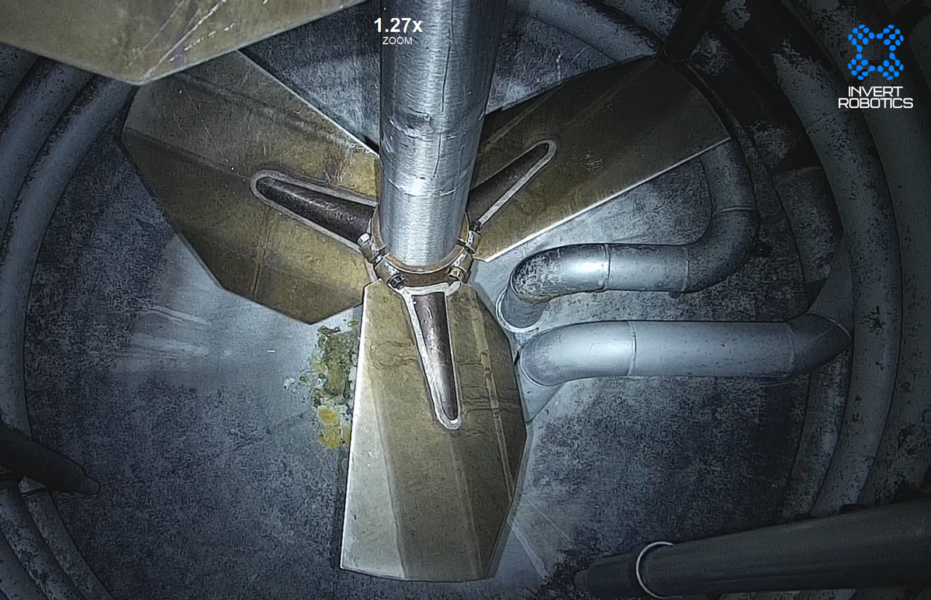

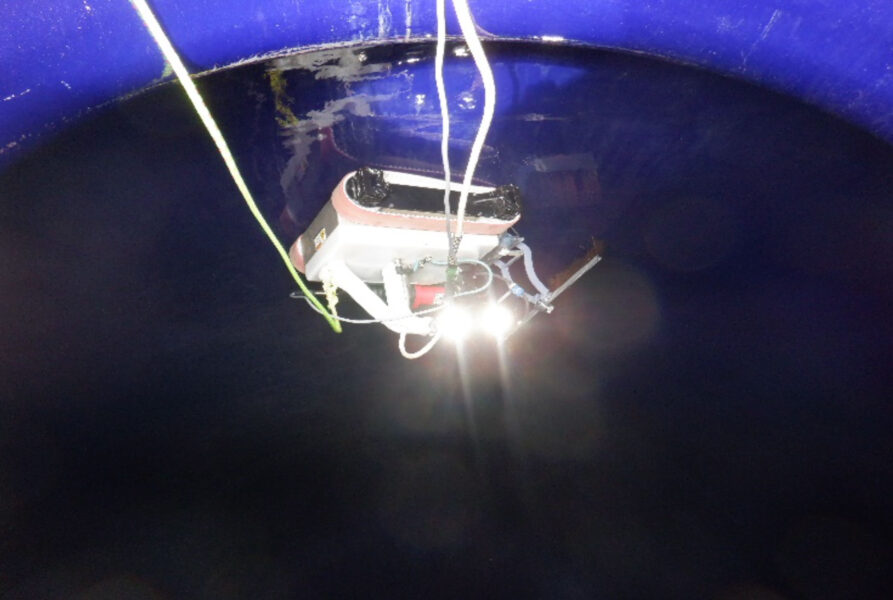

Remote visual & UT inspection of a small 60-cm diameter pump vessel

No need for hazardous human entry into a pump vessel! Invert Robotics’ robotic crawler enables safe remote inspections. The inspection of this, anchored in concrete, stainless steel pump vessel with a 60 cm diameter required some adaptations to our regular inspection tools. Our robot would not be able to navigate this small vessel. However, by […]

Robotic crawler: accurate UT measurements in challenging situations

Using our unique robot platforms to take UT measurements on a range of different assets – both internal and external – without having to enter confined spaces or work at height. Ultrasound wall thickness measurements are important data to help determine the condition of assets. Reason why, Invert Robotics has integrated Olympus state-of- the-art UT […]

Visual inspection and spark testing of glass lined storage tank

Full inspection solution: combined visual and D/C spark-testing inspection of a 40-year-old glass lined storage tank used for the storage of benzyl chloride. Our unique hybrid-crawler was originally designed for inspections of glass lined vessels: the combination of magnets and vacuum for adhesion ensures that the robot can drive around safely in such assets, without […]

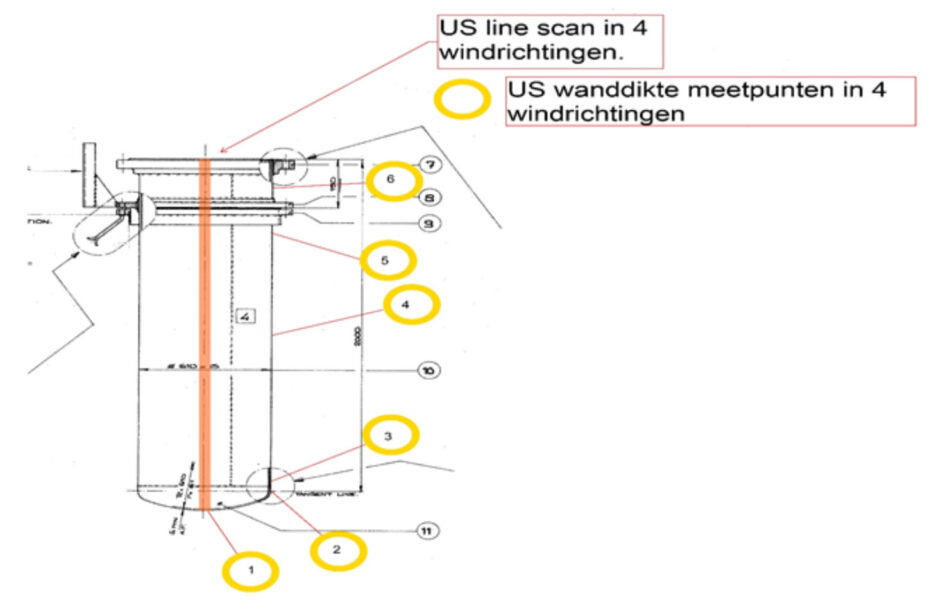

Combined NDT inspection: ultrasonic measurements and visual inspection of a carbon steel tank

High corrosion levels and a crowded interior provided the challenges for the inspection of this vessel. A custom-built ramp and a versatile robot enabled Invert Robotics to successfully inspect all areas of the slurry tank. At this zeolite production plant, located in the chemical cluster of Delfzijl in the Netherlands, Invert Robotics was tasked with […]

Repair or replace? Visual inspection of a fifty-year-old spray-dryer

Utilising its high-definition camera system, Invert Robotics conducted a visual inspection of a stainless-steel spray dryer within a day, delivering a highly detailed inventory of the vessels’ condition for the customer. This major Dutch silica producer requested visual inspection to help determine what to do with their spray dryer, commissioned in the 1970s. 50 years […]

Visual inspection of stainless-steel reaction vessels using vacuum crawler

Certification of pressure reaction vessels the safe and fast way: using inspection robots! Our client, a German-based chemical plant that manufactures synthetic resins is part of a global chemical giant. The facility in Germany specializes in batch production of over 200 different products. Numerous reaction vessel lines make this possible. Making sure that these vessels […]