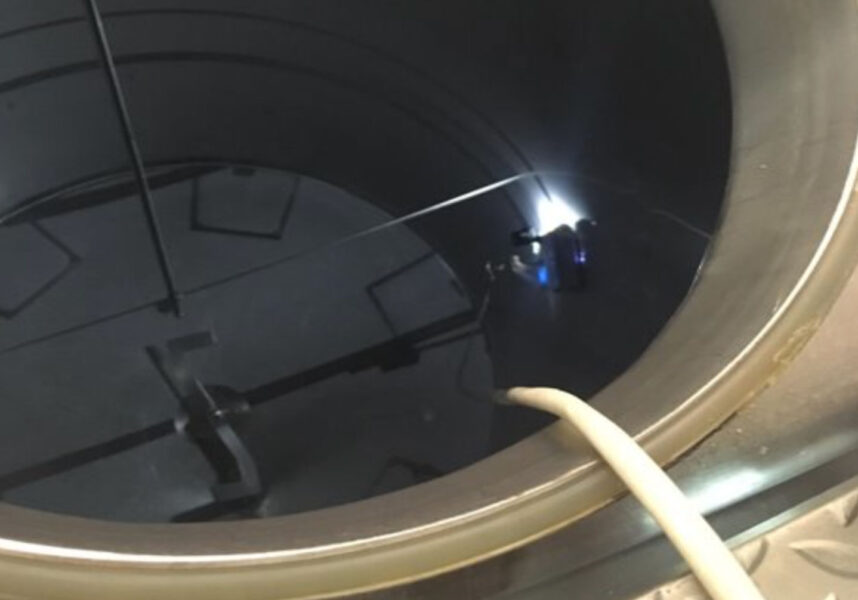

Mounting a hand-held A/C spark tester on our unique vacuum robot, inspection of ECTFE lining welds was done remotely for the very first time at this major producer of zeolite products.

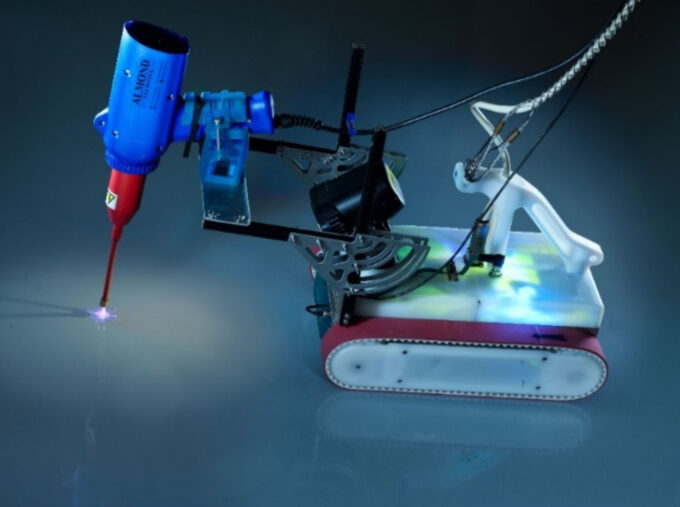

Invert Robotics is continuously looking to add NDT-tools to our robot’s repertoire. A regular customer in the chemical industry required an inspection using spark testing, to determine the quality of the ECTFE lining in their polyester tank.

Customised tooling

Our vacuum robot was equipped with a Buckley’s PST-100, 230V A/C spark tester on an adaptable frame, in a specially designed and 3D printed grip.

The voltage of the tester was set to the required strength, while the HD camera kept a close eye on the tester head, to spot any sparks that would indicate incomplete coverage.

Safe and fast

The inspection plan required all seams between the liner panels to be spark tested. After mapping the vessel, the robot drove a pre-determined pattern to ensure full coverage. In this way, the tank was back into commission without any need for hazardous confined space entry by humans.