Explorer de nouveaux lieux – inspection réussie du réseau de drainage inexploré d’un barrage hydroélectrique

Le défi Au cours d’un contrôle de sécurité quinquennal, des problèmes sont apparus concernant l’état du réseau de drainage souterrain du déversoir d’un barrage hydroélectrique à impact potentiel élevé en Nouvelle-Zélande. Par le passé, les méthodes traditionnelles de vidéosurveillance avaient fourni des résultats d’inspection non optimaux. De plus, la vidéosurveillance n’avait pas été en mesure […]

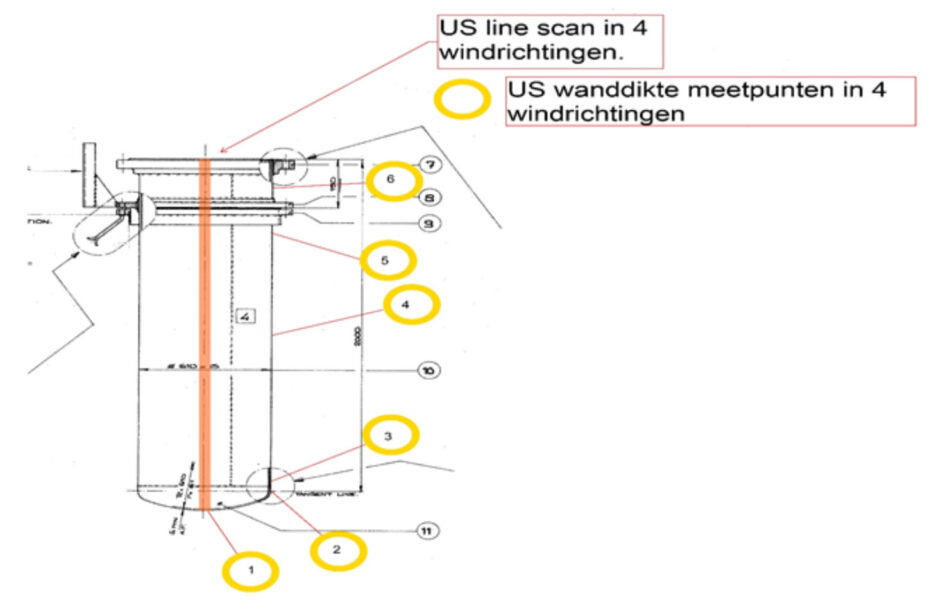

Remote visual & UT inspection of a small 60-cm diameter pump vessel

No need for hazardous human entry into a pump vessel! Invert Robotics’ robotic crawler enables safe remote inspections. The inspection of this, anchored in concrete, stainless steel pump vessel with a 60 cm diameter required some adaptations to our regular inspection tools. Our robot would not be able to navigate this small vessel. However, by […]

Using UT to inspect coal bin wear at a coal processing facility in Australia

In a collaborative project with a major Australian inspection services provider, Invert Robotics developed a custom M-serie robotic platform to take ultra-sonic wall thickness measurements without entering the confined space of a coal distribution hopper. Coal processing facilities utilise coal bins to manage the distribution of coal around there processing plants. The coal flows into […]

Successful remote 3D scan of iron ore chute at Western Australia mine

Invert Robotics developed a bespoke crawler inspection platform to obtain 3D scan data without entering the high risk confined space area below a 250,000 tonne iron ore stockpile. After a previous collaborative inspection with Invert Robotics, this mine in Western Australia once more called on us. This time they challenged us to devise a method […]