Exploring new worlds – successful inspection of uncharted drainage network of hydro-dam

The challenge During a 5-yearly safety review, issues appeared regarding the condition of the spillway under-drainage network of a High Potential Impact Classification hydro-dam in New Zealand. Traditional CCTV methods had – in the past – delivered sub-optimal inspection results. In addition, CCTV had been incapable of inspecting the lateral drains accessed via the main […]

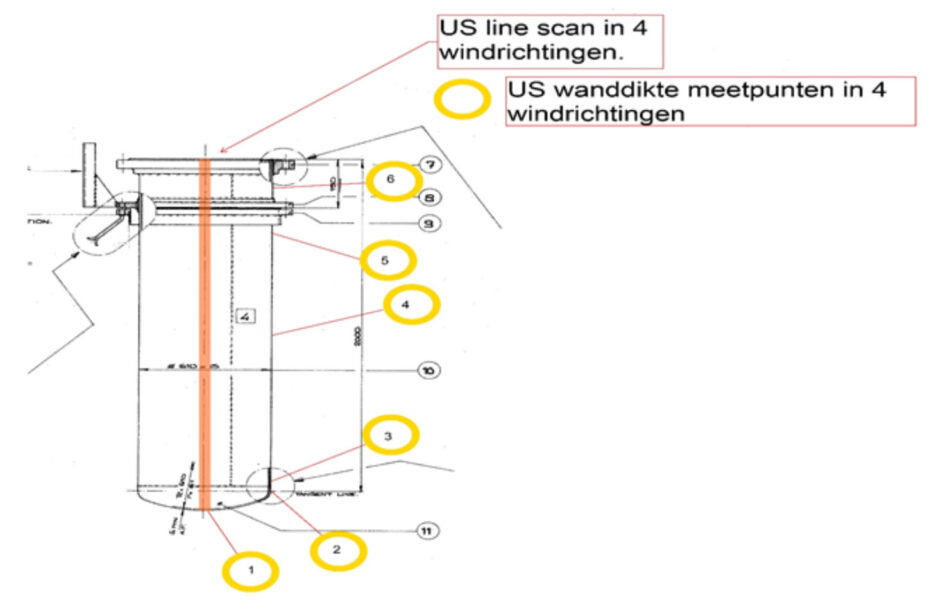

Remote visual & UT inspection of a small 60-cm diameter pump vessel

No need for hazardous human entry into a pump vessel! Invert Robotics’ robotic crawler enables safe remote inspections. The inspection of this, anchored in concrete, stainless steel pump vessel with a 60 cm diameter required some adaptations to our regular inspection tools. Our robot would not be able to navigate this small vessel. However, by […]

Using UT to inspect coal bin wear at a coal processing facility in Australia

In a collaborative project with a major Australian inspection services provider, Invert Robotics developed a custom M-serie robotic platform to take ultra-sonic wall thickness measurements without entering the confined space of a coal distribution hopper. Coal processing facilities utilise coal bins to manage the distribution of coal around there processing plants. The coal flows into […]

Successful remote 3D scan of iron ore chute at Western Australia mine

Invert Robotics developed a bespoke crawler inspection platform to obtain 3D scan data without entering the high risk confined space area below a 250,000 tonne iron ore stockpile. After a previous collaborative inspection with Invert Robotics, this mine in Western Australia once more called on us. This time they challenged us to devise a method […]