Full inspection solution: combined visual and D/C spark-testing inspection of a 40-year-old glass lined storage tank used for the storage of benzyl chloride.

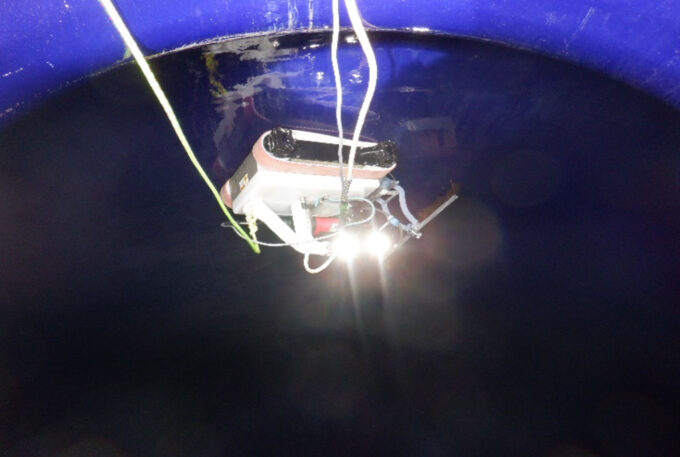

Our unique hybrid-crawler was originally designed for inspections of glass lined vessels: the combination of magnets and vacuum for adhesion ensures that the robot can drive around safely in such assets, without the risk of damaging the glass lining.

Full inspection services

By integrating a Buckley’s D/C spark tester onto the robotic crawler, Invert Robotics now offers a full inspection solution for such glass lined assets, without the necessity for human entry into a confined space.

This specific inspection consisted of two main components. First, a full visual inspection of the asset was required to find and localise any indications of defects. The results of the visual inspection were used to efficiently spark test all the defect indications that were found.

Back into operation fast

Within just four hours, the tank had been fully inspected and re-certified by the notified body representative, who was present during the inspection. As a result, the tank was back in operation fast, for at least another ten years.