Ultrasonic measurements and visual inspection of a carbon steel tank.

High corrosion levels and a crowded interior provided the challenges for the inspection of this vessel. A custom-built ramp and a versatile robot meant that Invert Robotics delivered all requested information from all areas of the slurry tank

At this zeolite production plant, located on the chemical cluster of Delfzijl in the Netherlands, Invert Robotics was tasked with the inspection of a more than thirty-year-old slurry tank. Both visual inspection and UT wall-thickness measurements were requested by the customer.

The heavily corroded surface combined with the inner layout including an agitator and baffles running up to the roof made inspection of this vessel challenging.

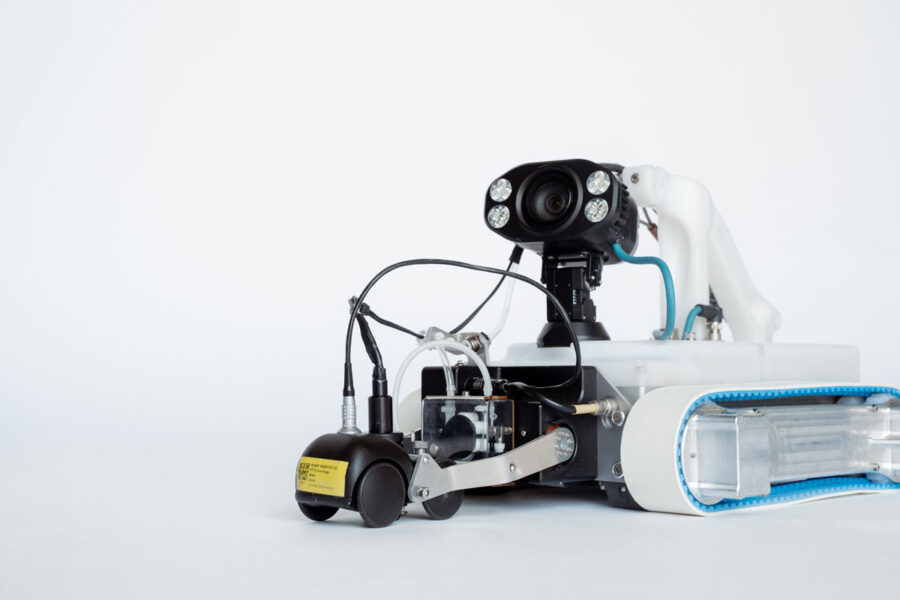

A custom ramp was built to ensure the robot could reach even the most difficult to reach areas of the slurry-tank. Utilizing the state-of-the-art camera and its 30x optical zoom function and an Olympus 38-DL UT-probe mounted in front of the robot as a buggy, Invert Robotics successfully inspected the slurry-tank using both required methods.

Within one week the required solutions for a successful inspection were created and a full status report was delivered. The result: a very satisfied customer who is now looking forward to doing more inspections using our robot crawler.