In for a challenge? Inspecting newly delivered, damaged wine vessels

What happens when a wine manufacturer finds out that a major order of wine tanks shows serious quality issues, with poor quality mechanical welds? With the tank manufacturer having filed for bankruptcy reclaim isn’t an option. The only possible course of action to minimise potential significant losses is to check faulty welds, repair them and […]

Inspection and repair in under 24 hours instead of 9 days

Thanks to our unique V-series crawler inspection robot – and in collaboration with rope access welding crews – Invert Robotics has replaced a 9-day inspection and repair cycle using scaffolding with a 1-day cycle with only minimal confined space access. Not surprisingly, by Europe’s largest and most advanced dairy processing plant has entrusted the inspection […]

Robotic crawler: accurate UT measurements in challenging situations

Using our unique robot platforms to take UT measurements on a range of different assets – both internal and external – without having to enter confined spaces or work at height. Ultrasound wall thickness measurements are important data to help determine the condition of assets. Reason why, Invert Robotics has integrated Olympus state-of- the-art UT […]

Combined NDT inspection: ultrasonic measurements and visual inspection of a carbon steel tank

High corrosion levels and a crowded interior provided the challenges for the inspection of this vessel. A custom-built ramp and a versatile robot enabled Invert Robotics to successfully inspect all areas of the slurry tank. At this zeolite production plant, located in the chemical cluster of Delfzijl in the Netherlands, Invert Robotics was tasked with […]

Visual inspection of stainless-steel reaction vessels using vacuum crawler

Certification of pressure reaction vessels the safe and fast way: using inspection robots! Our client, a German-based chemical plant that manufactures synthetic resins is part of a global chemical giant. The facility in Germany specializes in batch production of over 200 different products. Numerous reaction vessel lines make this possible. Making sure that these vessels […]

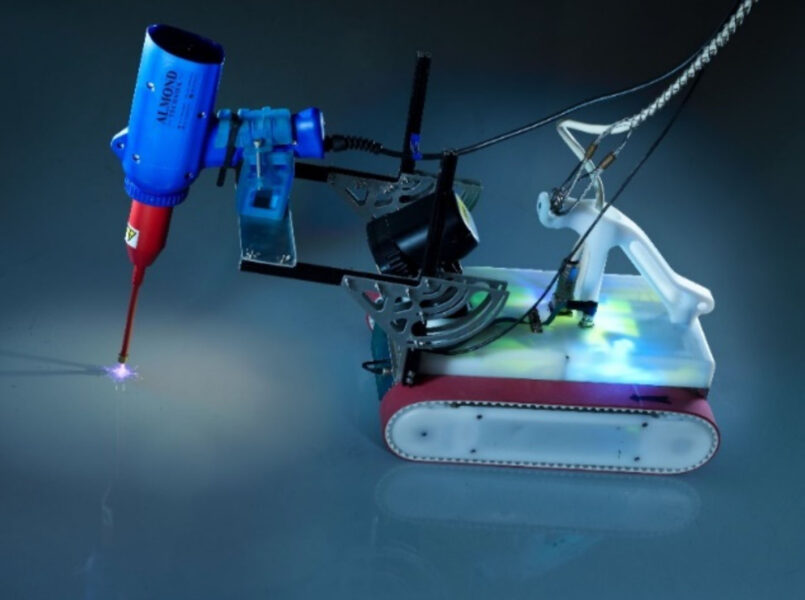

Spark testing ECTFE lining in a fibreglass reinforced polyester storage tank

Mounting a hand-held A/C spark tester on our unique vacuum robot, inspection of ECTFE lining welds was done remotely for the very first time at this major producer of zeolite products. Invert Robotics is continuously looking to add NDT-tools to our robot’s repertoire. A regular customer in the chemical industry required an inspection using spark […]

Collaborative project with major Dutch oil company results in first automated UT measurements in aluminium tank

Invert Robotics’ unique suction-based crawler inspection platform was used to take ultrasonic wall thickness measurements without the need for confined space entry. A major Dutch oil company approached Invert Robotics after a demonstration organised by Sprint Robotics. They asked us to add an Olympus DL38 ultrasonic thickness probe on our suction-based crawler platform. The objective […]

Milk Trucks

How this major dairy company is maximising product safety in milk trucks the safe, fast and secure way Product safety is key in the food and dairy processing industry. To ensure maximum hygiene, it’s essential that milk trucks are in prime condition with no risk of bacteria growing on residue or in surface pits or […]

Beer brewery

How leading breweries are making their asset inspection safer and faster As in all production processes, employee safety is paramount in the beer brewing process. It’s why a global market leader now has tank inspections carried out by a crawler robot. In doing so they are minimising the need for hazardous entry into confined spaces […]

Pharmaceutical pressure vessels

Measuring pitting the safe and fast way In the pharmaceutical industry everything revolves around safety and compliance. A global pharmaceutical company with over 60 pressure vessels of varying sizes on their Asian ma- nufacturing site was looking for an asset inspection solution that would minimise downtime, without compromising on safety or compliance. With vessels requiring […]