Compliance, safety and cost reduction are key drivers in the chemical industry. Our high-tech, robust and versatile robotic crawlers are enabling clients to maximize their performance in all three areas.

Partnering with international inspection companies, we conduct industry-certified, non-destructive and testing inspections on your assets according to EEMUA and API standards.

We work in close collaboration with certified international inspection companies. Our robots operate in compliance with all legal industry requirements.

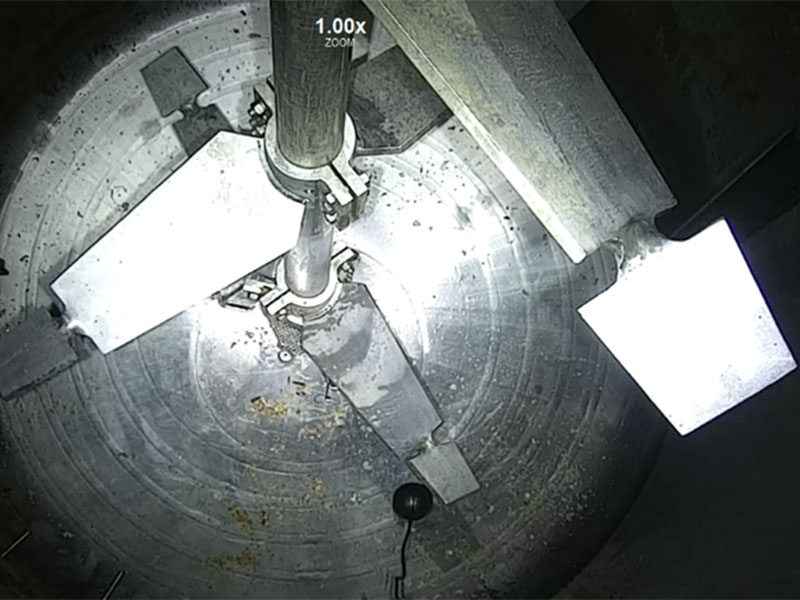

Boost employee safety. Our remote inspection technology is a highly accurate method for inspecting confined spaces, without requiring human entry.

Whatever the smooth surface to be inspected, our robots do the job. They have been specifically designed to leave no marks on damage-susceptible surfaces such as glass, rubber or plastic lined vessels, guaranteed.

Keeping your critical assets up and running at all times is paramount. You know how important it is to act immediately on any detected corrosion- or stress-related fractures. Real-time streaming of data enables same or next-day repairs.

Make informed decisions to optimize productivity and identify work required to sustain asset operations over time. Share inspection insights and asset maintenance issues from the comprehensive digital report with engineering and operations.

Real-time viewing by inspection engineer of inspection findings for immediate action. Highly accurate localization and marking of defects for follow-up. Full digital report provides a clear insight into asset health.