Partnership for professional rope access tank repair in Food Production

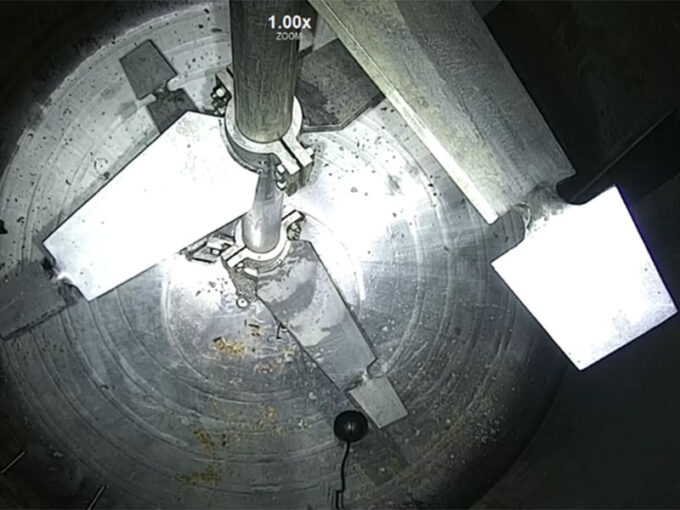

Inspection work carried out by us using our robotic platform in a dryer of a US-based dairy company, revealed that

Inspection work carried out by us using our robotic platform in a dryer of a US-based dairy company, revealed that

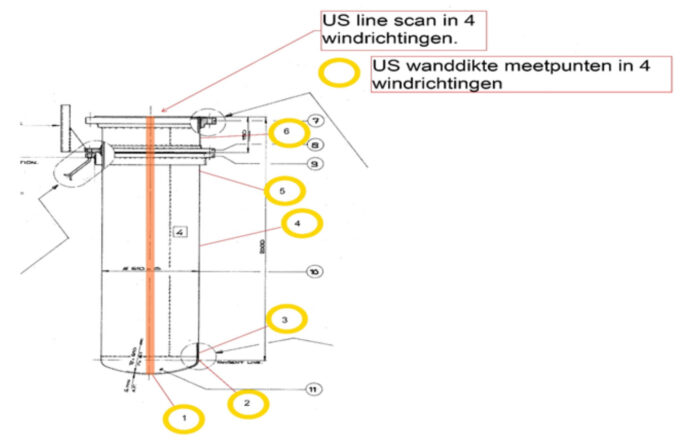

The inspection was carried out by a team of trained and certified personnel from Invert Robotics and Amotec AG. Non-destructive

Recently, we partnered with leading global inspection company SGS in Pakistan to carry out a Level 3 inspection and UT

Reducing costs while increasing efficiency, effectiveness and safety of asset inspections are top priorities for asset owners and maintenance managers.

The challenge During a 5-yearly safety review, issues appeared regarding the condition of the spillway under-drainage network of a High

As robotic inspection company we are the trusted inspection partner of leading French dairy producers. Based on our successful track

What happens when a wine manufacturer finds out that a major order of wine tanks shows serious quality issues, with

Collaboration project between CS Energy – a major Australian electricity generator – and Invert Robotics results in the first remote

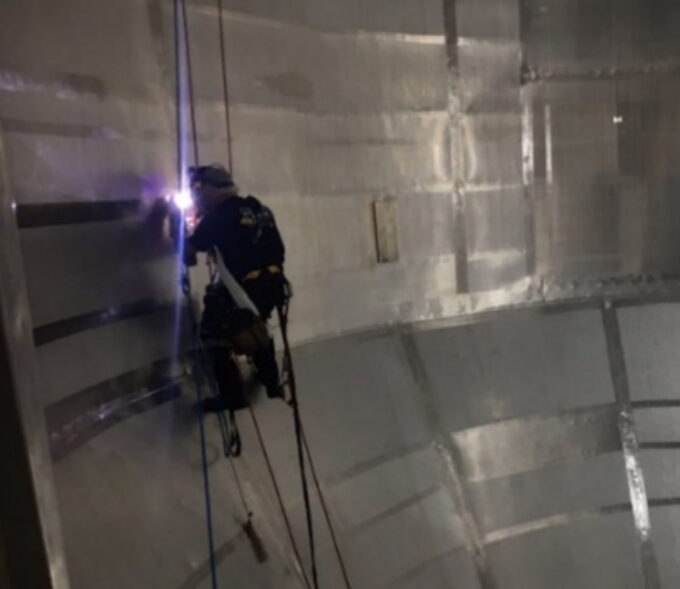

Thanks to our unique V-series crawler inspection robot – and in collaboration with rope access welding crews – Invert Robotics

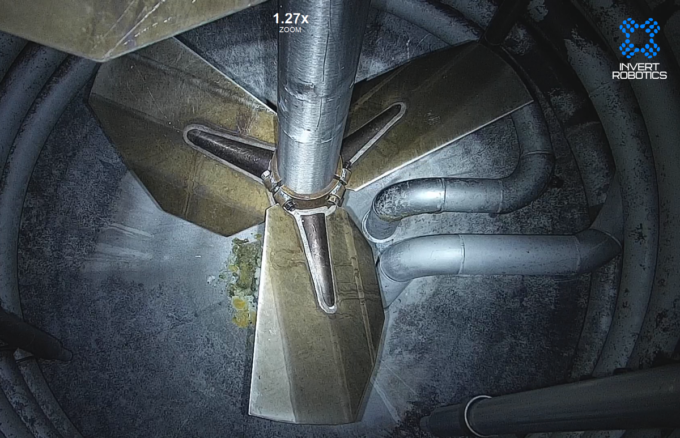

No need for hazardous human entry into a pump vessel! Invert Robotics’ robotic crawler enables safe remote inspections. The inspection

Using our unique robot platforms to take UT measurements on a range of different assets – both internal and external

Full inspection solution: combined visual and D/C spark-testing inspection of a 40-year-old glass lined storage tank used for the storage

High corrosion levels and a crowded interior provided the challenges for the inspection of this vessel. A custom-built ramp and

Utilising its high-definition camera system, Invert Robotics conducted a visual inspection of a stainless-steel spray dryer within a day, delivering

Certification of pressure reaction vessels the safe and fast way: using inspection robots! Our client, a German-based chemical plant that

A complex inspection job: an insulated 600 m3 resin tank was equipped with a large heating coil on the floor,

Mounting a hand-held A/C spark tester on our unique vacuum robot, inspection of ECTFE lining welds was done remotely for

Invert Robotics’ unique suction-based crawler inspection platform was used to take ultrasonic wall thickness measurements without the need for confined

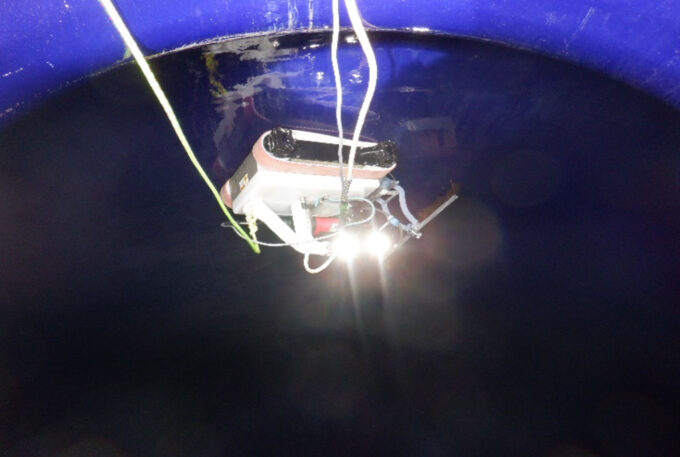

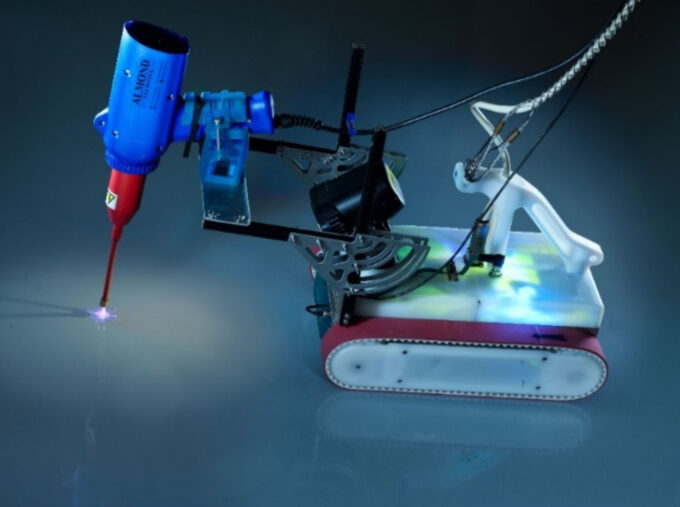

In a collaborative project with a major Australian inspection services provider, Invert Robotics developed a custom M-serie robotic platform to

Invert Robotics developed a bespoke crawler inspection platform to obtain 3D scan data without entering the high risk confined space

How this major dairy company is maximising product safety in milk trucks the safe, fast and secure way Product safety

How leading breweries are making their asset inspection safer and faster As in all production processes, employee safety is paramount

Measuring pitting the safe and fast way In the pharmaceutical industry everything revolves around safety and compliance. A global pharmaceutical

Leave the internal inspection to the robots! The mandatory periodical re-certification of the pressurised reaction line requires internal visual inspection

Inspection and repair entrusted to Invert Robotics for the third year running by Europe’s largest and most advanced dairy processing

Ultrasonic measurements and visual inspection of a carbon steel tank. High corrosion levels and a crowded interior provided the challenges